110-4106 Micro Drill System |

INS 110-4106 |

This versatile tool is ideal for milling, drilling, grinding, cutting, and sanding circuit boards. Use it to remove coatings, cut circuits, cut leads, drill holes, and perform many other procedures using interchangeable bits.

Unlike most hand-held tools, the Micro-Drill has a tiny, high-speed DC motor in the handpiece, eliminating bothersome drive cables and giving the technician precise control. A separate power supply keeps the handpiece lightweight and reduces fatigue.

| ■ | High quality construction for delicate work. |

| ■ | Flexible telephone-style cord eliminates bothersome drive cables. |

| ■ | Quick change chuck for easy bit replacement. |

| ■ | Versatile forward, reverse, and variable speed up to 40,000 RPM |

| ■ | Lightweight, ergonomically designed hand piece reduces fatigue. |

| ■ | Dual voltage, 120 VAC, 220 VAC. A plug meeting the local requirements may be needed. |

Operation

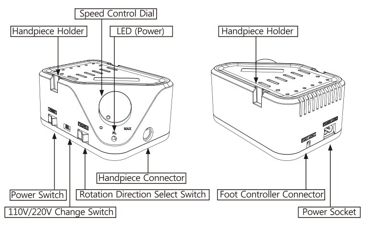

- Connect the power cord to the power socket.

- Connect the foot controller cord when using the foot controller.

- Connect the handpiece cord.

- Check the power switch setting. Set for either 110 volts or 220 volts.

- Turn the handpiece handle to open the chuck, insert a tool or ball mill, and then lock the handpiece chuck by turning the handle.

- Set the rotation using the rotation switch.

- The Handpiece is now ready for operation. The speed is adjusted using the Speed Control Dial.

- Depress the foot pedal and gradually turn the speed control dial until the desired speed is attained.

- It is normal for the handpiece to warm up slightly on continued use. Do not use in wet locations.

- If the unit fails to operate, open the base and check the internal fuse.

Suggested Maintenance

- Carbon brushes in the handpiece motor are designed for long life, approximately 1,000 hours. Carbon brushes should be replaced periodically, approximately once each year.

- Wipe the handpiece only with isopropyl alcohol and avoid getting wet.

|