| Qty |

Part No. |

Description |

| 2 |

115-3120 |

Setting Tool, Small |

| 2 |

115-3126 |

Setting Tool, Large |

110-5202 Eyelet Press

This rugged, heavy-duty press precisely forms eyelets in circuit boards for repair or assembly, ensuring the eyelets meet industry guidelines.

Includes two #115-3120 Setting Tool, Small, and two #115-3126 Setting Tool, Large, to form a large range of eyelets. This Eyelet Press will deliver years of maintenance-free reliable production.

| ■ | Heavy duty construction to properly form eyelets per IPC guidelines. |

| ■ | Includes Setting Tools to properly form a large range of eyelet sizes. |

|

|

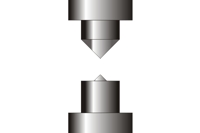

Figure 1: The small cone tip end of the lower Setting Tool faces up. The large cone end of the upper setting tool faces down.

|

Eyelet Press Setup

- Be sure the upper and lower Setting Tools are perfectly aligned. The tips should touch when the press is lowered. If the tips are not aligned, loosen the four mounting bolts and adjust as needed.

- If needed, drill out the plated hole removing all the plating. The drilled hole should be .001" - .005" (.025 - .125 mm) larger than the eyelet outside diameter. Use caution when working on a circuit board with inner layers.

- Insert the proper Setting Tool into the Tool Holder installed in the base of the Eyelet Press. The small cone tip end of the Setting Tool should be facing up. Tighten the set screw to secure it in position. (See Figure 1)

|

|

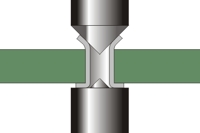

Figure 2: Flare the eyelet barrel using the flared end of the setting tool.

|

Insert the proper Setting Tool into the ram of the Eyelet Press. The larger cone end of the Setting Tool should be facing down. No tightening should be needed; springs inside the ram should hold the Setting Tool in position. (See Figure 1)

Visit the follow pages for details instructions.

|