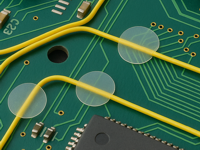

310-0651 Wire Dots, .256" (6.5 mm) Round

$49.00 pkg/450

Wire Dots are a wire tacking system consisting of pre-cut shapes of a thin, flexible polymer film coated on one side with a high-performance, electronics grade permanent pressure-sensitive adhesive. The result is a highly conformable, high-strength bond.

The adhesive on Wire Dots is commonly used for graphic attachment and membrane switch applications because it has excellent long-term quality, consistency, and durability. Wire Dots perform well after exposure to high humidity, UV, immersion in water, and hot/cold cycles.

Wire Dots will hold secure after exposure to numerous chemicals including cleaning solutions/sprays, saponifiers, mild acids, and alkalies, and will hold secure through a typical circuit board hot water wash.

Sold in packages. DATA SHEET

| Ordering | ||

| 310-0651 | 310-0651 Wire Dots, .256" (6.5 mm) Round | |

Material Properties ▼

| Cover Film | Clear Polyester Film 1.0 mil (.025 mm) Thick |

| Adhesive | High performance Acrylic Adhesive 5.2 mils (0.13 mm) Thick (3M #3468MP) |

| Relative High Temperature Operating Ranges | Short term (minutes/hours) 400°F (204°C) Long term (days/weeks) 300°F (149°C) |

| Application | Specifically designed for long term bonding to printed circuit boards and high surface energy plastics for the aerospace, medical and industrial equipment, automotive, appliance and electronic markets. |

| Shelf Life | Minimum 12 months. |

| Safety Data Sheet | msds_wire_dots |

Physical and Thermal Properties ▼

| Property | Typical Value | Unit | Test Method |

| Peel Strength 72 hrs @ 22 C | 84 | 0z./in. | ASTM D3330 Modified |

| Static Shear Strength 72 F (22 C) / 1000g | >10,000 | min | ASTM D3654 |

| Tensile Strength (Yield) 72 F (22 C) | >2600 | psi | ASTM D2370 |

| Elongation | 100 | % | ASTM D2370 |

| Thermal Conductivity | 0.17 | w/m-k | ASTM C518 |

| Coefficient of Thermal Expansion | 5.5 x 10 -4 | m/m/C | ASTM D696 25-175C |

Electrical Properties ▼

| Property | Typical Value | Unit | Test Method |

| Dielectric Strength | 1700 | volts/mil | ASTM D149 |

| Dielectric Constant 25 C, 1 kHz | 3.4 | ------ | ASTM D150 |

| Dissipation Factor 25 C, 1 kHz | 0.018 | ------ | ASTM D150 |

| Surface Resistivity - Adhesive Layer | >1 x 10 14 | ohm/square | ASTM D257 |

| Surface Resistivity - Polymer Film Layer | >1 x 10 16 | ohm/square | ASTM D257 |

| Volume Resistivity - Adhesive Layer | >1 x 10 15 | ohm/cm | ASTM D257 |

| Volume Resistivity - Polymer Film Layer | >1 x 10 18 | ohm/cm | ASTM D257 |

| Insulation/Moisture Resistance - Adhesive Layer | >1 x 10 11 | ohm | MIL-I-46058C (100 VDC 60 sec) |

| Insulation/Moisture Resistance - Polymer Film Layer | >1 x 10 12 | ohm | MIL-I-46058C (100 VDC 60 sec) |

| Voltage Breakdown | 3500 | volts | ------ |

Classifications ▼

| Harmonize Code | 8207.19.5030 |

| Export Administration Regulations (EAR) | EAR99 |

| Export Control Classification Number (ECCN) | Not Applicable |

Contact Us Form ▼