110-5202 Eyelet Press |

INS 110-5202 |

| Qty |

Part No. |

Description |

| 2 |

115-3120 |

Setting Tool, Small |

| 2 |

115-3126 |

Setting Tool, Large |

| 1 |

110-5212-2 |

Tool Holder Base |

| 1 |

950-1318 |

Eyelet Press, Sub |

| 4 |

950-3126 |

Bumper, Adhesive Backed |

| 1 |

977-0838 |

Screw, Set, Flat Point, #8-32 x 3/8" Long |

| 1 |

980-1117 |

Thumb Screw, 8-32 Thread |

| 1 |

980-2375 |

Name Plate, CircuitMedic |

This rugged, heavy-duty press precisely forms eyelets in circuit boards for repair or assembly. The heavy-duty construction ensures eyelets are formed per IPC guidelines. The CircuitMedic Eyelet Press will deliver years of maintenance-free, reliable production. Eyelets are sold separately.

- Throat Depth: 6.50" (16.50 cm)

- Minimum Throat Opening: 1.00" (2.54 cm)

- Tooling Shank Size: .203" (5.15 mm) Diameter

- Weight: 28 lbs. (13 kg.)

Eyelet Press Setup

-

|

|

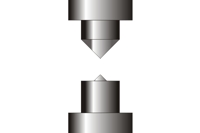

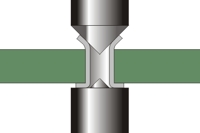

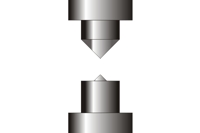

Figure 1: Tool orientation.

|

Be sure the upper and lower Setting Tools are perfectly aligned. The tips should touch when the press is lowered.

If the tips are not aligned, loosen the four mounting bolts and adjust as needed.

|